ISS 3D printer makes first part in space

Scientists will study if microgravity impacts the 3D-printing process

A 3D printer aboard the International Space Station manufactured the first 3D-printed object in space this week, NASA says.

The machine printed a replacement part for itself, in a "historical" step that can change the way exploration missions receive needed hardware.

"This is actually truly a historical moment,"said NikiWerkheiser, the project manager for theISS3Dprinter, in a NASA YouTube video. "Since the inception of the human space program, we have been completely dependent on launching every single thing we need from Earth to space ... I think we're making history for the first time ever being able to make what we need when we need it in space."

- How does 3D printing work?

- Photo gallery: 3D printed objects featured atexhibition

- Where to find cool stuff to 3D print

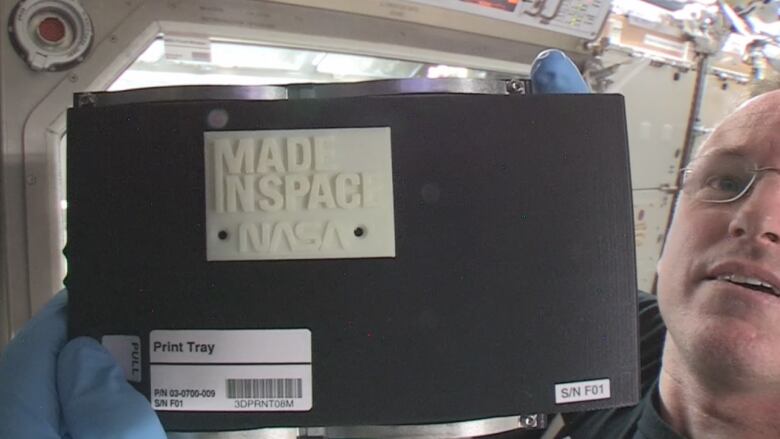

The ISS 3D printer createdafaceplateof theextruder'scasing for its first print job, according to NASA's website.

Werkheiser said the team selected this part for its first print because the machine needs to be able to print spare parts for itself if astronauts will be relying on it to "make spare and replacement parts for critical items in space."

"If a printer is critical for explorers, it must be capable of replicating its own parts, so that it can keep working during longer journeys to places like Mars or an asteroid. Ultimately, one day, a printer may even be able to print another printer."

Microgravity may impact3D-printing process

Barry Wilmore, a NASA astronaut and ISS commander, installed the printer last week. The printer heats up a plastic filament and builds objects one layer at a time.

Wilmore conducted two calibration test prints between Nov. 17 and 20 to make sure the printer was properly prepared to print its first part.

This may change how we approach getting replacement tools and parts to the space station crew, allowing them to be less reliant on supply missions from Earth.- AaronKemmer, Made in Space CEO

Ground controllers sent the printer a command to work on the spare part on Nov. 24. The next day, Wilmoredetached the faceplate from the printer tray to inspect it.

When Wilmore removed the object from the printer tray the adhesion was stronger than astronauts anticipated. As astronauts print more objects they will study whether layer bonding is different in microgravity based on these findings.

"As we print more parts, we'll be able to learn whether some of the effects we are seeing are caused by microgravity or just part of the normal fine-tuning process for printing," Wilmoretold NASA.

The team is now conducting another calibration test as the printer needs to be precisely aligned for each print. After the third calibration test, the team will be able to attempt to 3D print another spare part.

The 3D printed pieces will come to Earth in 2015 where scientists will compare them to identical ground control samples.

"When we get the parts back on Earth, we'll be able to do a more detailed analysis to find out how they compare to parts printed on Earth," Wilmore said.

Using the 3D printer at the ISS"is a transformative moment in space development," said Aaron Kemmer, the CEO of Made in Space, which worked with NASA on creating the 3D printer being used.

"This may change how we approach getting replacement tools and parts to the space station crew, allowing them to be less reliant on supply missions from Earth."

_(720p).jpg)

OFFICIAL HD MUSIC VIDEO.jpg)

.jpg)