Finding Canada's 'cold chain': How domestic industry can help with COVID-19 vaccine distribution

Danby appliances in Guelph sped up plans to produce a very cold freezer

Ontario companies are stepping up with solutions whichcould help makesure the "cold chain" is in place when it comes time to distributingCOVID-19vaccines.

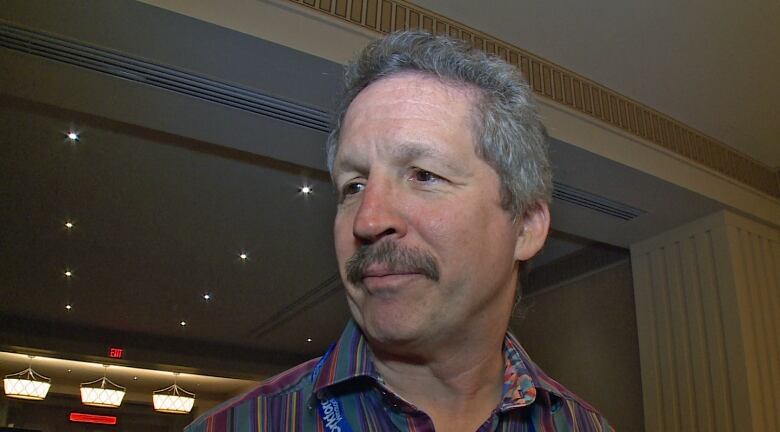

"I believe these might be needed for [the] vaccine and if they're not needed then great, but it is right in our wheelhouse," JimEstill, chief executive officer of DanbyAppliances in Guelph, told CBCNews.

Danby manufactures half a million freezers every year,and while it has never produced a freezer capable of reaching 70C, it was already on its drawing board.

"We should totally contribute what we can to this cause," Estill said.

While the rollout plan for COVID-19 vaccines in Canada is still largely a mystery, what's knownis that some of those vaccines will have to be kept in very cold temperatures.

Vaccines likethe one being developed by Moderna require storage at 20 degrees C, andthe vaccine being developed at the University of Oxfordneeds to be stored just above zero.

Pfizer reported preliminary findings of its phase 3 trials last month, and while the news was celebrated, the fact that it needed to be stored at 70 Cpresented an immediate challenge.

I honestly don't know what the demand will be. I don't know whether we're going to make 1,000 or 10,000.-Jim Estill

"When we first heard about it two or three weeks ago, [we] just put pedal to the metal and released them to the market," Estill said.

As far as production goes, Estill said thatbecause the freezers are specialized and would require installation, the company would likely need to bring more people on.The freezers would range in price from $10,000 to $20,000, and it wouldtake about fivemonths to manufacture and ready them for distribution.

"I honestly don't know what the demand will be. I don't know whether we're going to make 1,000 or 10,000," Estill said.

Industry on stand by

Canadian industriespulled togetherat the onset of the pandemic when a call went out for ventilators and personal protective equipment, as well ashand sanitizer to help fill shortages.

- Vaccine priority list must be refined to match available doses: Tam

- U.K. approves Pfizer coronavirus vaccine for emergency use

- The pandemic was already polarizing now vaccines have become partisan as well

Assisting in that effort wereseveral member companies of theAutomotive Parts Manufacturers Association who helped by making face shields and components for ventilators. They are ready to lend another hand if called upon in the effort to distribute vaccines.

"We're all reading the news in real time, including both levels of government," said Flavio Volpe, APMA president.

Volpesaid that he is in touch with the provincial and federal governments and should know by mid- to late-December how they can help.

"What we're doing is we're doing the due diligence to know,number one:arethe products we make or could retool to make can be helpful?I think the first answer is yes.And number two:can we do them at the scale in a production schedule that makes a dent?"

Volpe said that companieswhich are able to ramp up production at the beginning of the new year would be more helpful than those that could get up and running by the summer.

Volpe saidOntario auto parts makers do about $100 millionworth of shipments in a day, and when it added medical supplies, that only created another three or four days worth of shipments in total. Therefore, he says, capacityis not an issue.

"It's really a function of, do you have floor space and do you have time in the schedule," Volpe said.

The answer from an operational standpoint is always a yes, and then the deeper dive is: what about the raw materials.- Flavio Volpe

He said companies can bring on a third shift to help ramp up production, and as far as space, he cites one company that began making masks dedicated about fiveper cent of its floor space to that project, which wasn't anissue at all.

"You're talking about an industry that employs 100,000 people ... not a problem," he said.

Volpealso pointed toward other solutions to make shipments, such as creatingStyrofoam cooler-like containers used by couriers and short-haul delivery companies, as well as an already existing "cold chain" in Canada, the one used to ship bovine semen, which keeps the product at cold temperatures usingcast metal containers with liquid nitrogen to transport it.

He said the challenge is getting enough materials to build the solutions.

"The answer from an operational standpoint is always a yes, and then the deeper dive is:what about the raw materials?" Volpe said.

_(720p).jpg)

OFFICIAL HD MUSIC VIDEO.jpg)

.jpg)