PrintAlive 3D skin tissue printer wins Canadian Dyson Award

Cells from burn victims could be used to print skin grafts

A 3D printer that may one day generate new skin for burn victims has won a $3,500 prize and a chance to compete internationally for $50,000 more.

The PrintAlive Bioprinter developed by University of Toronto engineering students Arianna McAllister and Lian Leng has won the top Canadian prize in the 2014 James Dyson Awards program.

Prizes in 18 countries have been given out by the James Dyson Foundation for student projects featuring the industrial or product designs that solve a problem.

In this case, the problem is severe burns that damage both the outer layer of skin, the epidermis, and the inner layer, the dermis, which are made of different cells in different structures, said Leng, a PhDstudent in mechanical and industrial engineering.

When that type of burn happens, "it's very difficult for the body to regenerate itself," she added in an interview with CBC News. In some cases, burn victims can die if their wounds aren't closed quickly.

Ideally, the patients' own cells should be used to close the wound to reduce complications and scarring, but that approach may be too slow, McAllistersaid. It typically takes at least 14 days for culturedskin cells to grow enough to be ready for grafting.

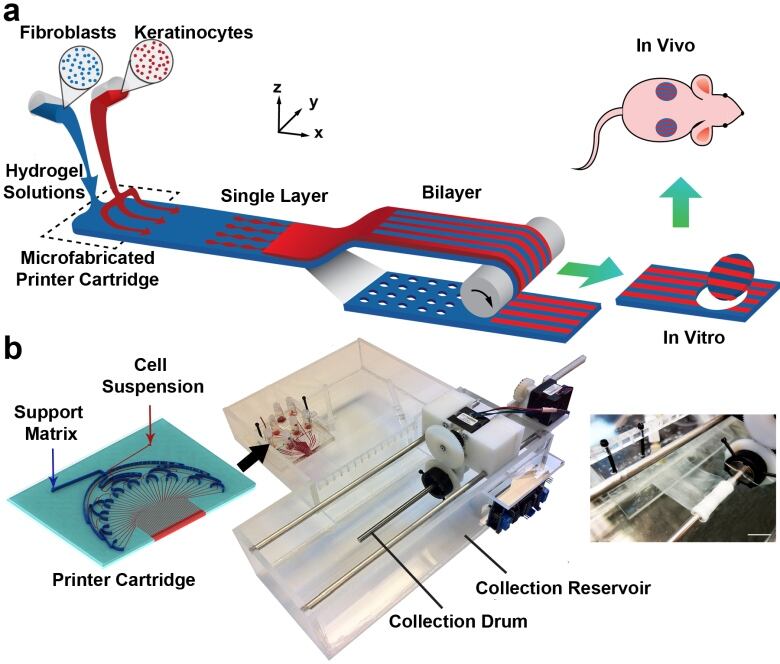

The 3D printer can rapidly create grafts using the patient's own cells by printing them out in patterns such as spots and stripes instead of as a continuous sheet that would require far more cells, said McAllister, who completed her master's degree at the University of Toronto's Institute of Biomaterial and Biomedical Engineering in January.

Human clinical trials about 3 years away

So far, the team's 3D-printed grafts of human skin have improved wound healing in immune-compromised mice. The team is hoping to move onto larger grafts in pigs, then to human clinical trials within two or three years.

Skin grafts have been traditionally impossible to create with3D printers because they involve complex layers of different cells that require different environments. Also, most 3D printers are designed to print hard materials instead of flexible materials like skin. That means skinlayers would collapse if printed using conventional 3D printers, Leng said.

Leng and McAllister worked with BoyangZhang, who has since completed his PhD,Axel Guenther, an associate professor of mechanical and industrial engineering at the University of Toronto,andburn surgeon Dr. Marc Jeschke at Sunnybrook Research Institute to develop a special kind of printer cartridge.

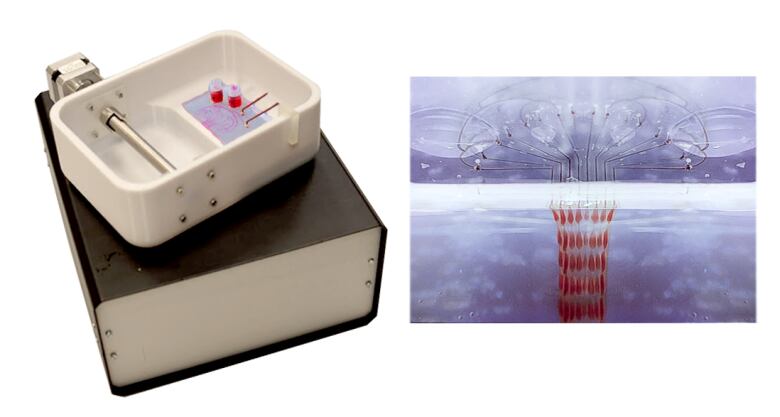

The cartridge contains tiny channels filled withskin cells and the liquid environment they require. The different cell types for the two different layers, along with their specialized liquid, are kept in two different channels.

Each layer is squirted out in liquid form into another liquid that causes it to solidify into a gel as it leaves the printer. The two layers are printed together, one on top of another, in the proper order, generating a biodegradable wound dressing containing skin cells that can be used to treat burns.

National winners and four runners-up from each country will have the chance to compete for an international prize of $50,000.

Canadian runners-up include:

- University of Waterloo students who developed EyeCheck, a smartphone app and camera that automatically provide vision checks and prescriptions, for use in the developing world.

- Another Waterloo team that developed Suncayr, a pen-like marker that lets people know when they need to reapply sunscreen.

- Students from Humber College in Toronto, who developed the Skorpion Rock Drill, a compact drill carrier intended to reduce injury in the mining industry.

- University of Victoria students who developed EcoSat, a nano-satellite that looks at the ability of pyrolitic graphite to repel a magnetic field in space.

A global short list will be announced on Oct. 16.Shortlisted teams will get the chance to send a video pitch to British inventor and multibillionnaire James Dyson, founder of the Dyson company and the James Dyson Foundation, which describes itself as "dedicated to helping young people think differently, make mistakes, invent and realize their engineering potential."

Dyson will choose the winner of the $50,000 grand prize on Nov. 6.

_(720p).jpg)

OFFICIAL HD MUSIC VIDEO.jpg)

.jpg)